Frequently Asked Questions

Frequently Asked Questions

- Is a spec sheet available for your optic mounts with length, material, and other data?

- Can I place a backorder request for out of stock items?

- Is the AK mount I purchased too short for my rifle?

- Is barrel heat transmitting up through my UltiMAK mount and into the optic a valid concern?

- Which kinds of Picatinny accessories (rings or bases, “rail grabbers”, “rail squeezers”) are compatible with UltiMAK mount rails?

- Why won’t certain aftermarket lower handguards fit with your AK optic mounts?

- How come your M6 mounts won’t fit Universal and other commercially made Carbines from the 1960s and ‘70s?

- How do I know if my M1 Carbine has a GI profile barrel and is therefore compatible with your M6 optic mounts?

- Why doesn’t the rail extend all the way back to the receiver on some mounts?

- Why don’t you publish torque specs in your installation instructions or on your website?

- Do you make a mount for my Saiga AK?

- Which mount fits my Palmetto State Armory AKM?

- Is a spec sheet available for your optic mounts with length, material, and other data?

- Can I place a backorder request for out of stock items?

- Is the AK mount I purchased too short for my rifle?

- Is barrel heat transmitting up through my UltiMAK mount and into the optic a valid concern?

- Which kinds of Picatinny accessories (rings or bases, “rail grabbers”, “rail squeezers”) are compatible with UltiMAK mount rails?

- Why won’t certain aftermarket lower handguards fit with your AK optic mounts?

- How come your M6 mounts won’t fit Universal or other commercially made Carbines from the 1960s and ‘70s?

- How do I know if my M1 Carbine has a GI profile barrel and is therefore compatible with your M6 optic mounts?

- Why doesn’t the rail extend all the way back to the receiver on some mounts?

- Why don’t you publish torque specs in your installation instructions or on your website?

- Do you make a mount for my Saiga AK?

- Which mount fits my Palmetto State Armory AKM?

Q: Is a spec sheet available for your optic mounts with length, material, and other data?

A: Indeed, there is. Click the buttons below to view or download a PDF file that lists the length, slot count, weight, and materials of every mount in our store.

Q: Can I place a backorder request for out of stock items?

A: Yes; you can place an order over the phone for items that are not currently in stock. Please call us at (208) 883-4734 or email us at steph@ultimak.com, and we will add your request to our backorder list. We can take payment information down, but will not charge your card until the day the product ships out. In order to streamline the process and to eliminate potentially long waits that can be caused by delays in the supply chain, backorders cannot be submitted online.

Q: Is the AK mount I purchased too short for my rifle?

A: If you ordered the mount that was recommended on our website for your particular AK, then the mount is most likely the correct length. UltiMAK AK mounts are always slightly shorter than the original gas piston tubes that they replace — usually between 1/16″ to 1/4″ shorter. This is an intentional design feature, as the included instructions for our AK mounts explain:

The UltiMAK Mount is designed to be clamped to the barrel, not held by the pin in the rear sight block. Since it clamps to the barrel, it aligns with the barrel. Since it is not held in by pushing between the gas block and rear sight block, the barrel can expand and contract from heat changes without affecting the mount.

The following video explains this design choice in greater detail and provides a visual demonstration as well:

Q: Is barrel heat transmitting up through my UltiMAK mount and into the optic a valid concern?

A: Under any kind of realistic use, no — our mounts do not get hot enough to cause problems for an optic. This is a question that comes up occasionally about our gas tube AK mounts, because the mount itself does get warm after repeat fire during a shooting session. However, unless you are emptying piles of pre-loaded magazines as fast as possible, this is nothing to worry about. We have verified this fact through extensive trials, and our customers have used our mounts for over two decades with virtually no reports of optics malfunctioning because of overheating.

We’ve fired thousands and thousands of rounds in “torture tests” in a variety of weather conditions, often employing fully loaded 75-round drums, and have never encountered a problem with an optic overheating on one of our mounts. It would theoretically be possible to damage such a mounted optic by overheating it through extreme practices, but we cannot imagine any real-life situation in which such a thing would happen. For one thing, most people could not carry enough ammunition — you’d have to be firing from an ammo supply truck, with another person or two loading magazines for you. So unless you’re planning on using your AK as a squad automatic, with prolonged automatic fire as you empty magazines in rapid succession, you have no reason to worry about your optic getting too hot on an UltiMAK mount.

Q: Which kinds of Picatinny accessories (rings or bases, "rail grabbers", "rail squeezers") are compatible with UltiMAK mount rails?

A: Almost anything that fits a standard Picatinny rail will fit our mounts, with only a few exceptions:

- LaRue throw-lever products will not fit our mounts because they require Picatinny rails with a higher vertical riser under the dovetail.

- EOTech products with proprietary quick release levers also will not fit our mounts due to the same reason — however — many EOTech products don’t feature this proprietary lever and therefore will fit our mounts. The A.R.M.S. throw-lever EOTech models will work, as will the standard, non-QD models.

Most of our mounts have the mount body under the dovetail falling away at a downward-sloping 45 degree angle. Therefore any rail mount which requires vertical space directly under the dovetail is going to interfere. It is impossible to know every device that might have a problem, but we can confidently say that the vast majority of “rail squeezers” are compatible with our mounts. Also, it is a certainty that, as of this writing, all Aimpoint products are compatible, as are the Primary Arms MicroDot products, and similar products from Bushnell, Sig Sauer, Trijicon, and many others. In short, while it is possible to find something that won’t fit one of our mounts, there is no shortage of compatible options whatsoever.

The reason we at UltiMAK design our Picatinny rails this way is to produce the lowest possible rail mounts. This allows a proper cheek weld to be obtained with the factory stock, and in many cases makes it possible to co-witness the factory iron sights with a low-mountable dot sight. To accomplish this twofold feat, it was necessary to eliminate — or nearly eliminate, in some cases — the vertical riser underneath the Picatinny dovetail. While much of the gun world is going to taller and taller sights and higher rails, UltiMAK takes the classic firearms and makes them compatible with modern optics.

Q: Why won't certain aftermarket lower handguards fit with your AK optic mounts?

A: We designed our AK optic mounts to fit with virtually all original (military) AKM handguards – in wood (aside from Chinese wood), Bakelite, polymer, or polymer and steel – which were standard at the time of the design process. If the designer of a new aftermarket handguard did not specifically make sure that his design was UltiMAK compatible, or did not use the original AKM pattern internal dimensions, it might not fit without alteration.

Magpul AK lower handguards are UltiMAK compatible. Our own ACR2 Modular railed AK lowers are UltiMAK compatible by design, as are any of the handguards sold on our website. We cannot vouch for any other. If you have an original military (inside) pattern lower, and it’s not Chinese wood, then you’re almost certainly good to go. There are however some very well-made AK military lookalikes which are not compatible because the internal dimensions do not follow the originals. If your aftermarket handguard is not from Magpul, you may need to do some simple routing, chiseling or Dremeling to make room between the barrel and the inside of the handguard (this is easily done).

As an aside: we created one of the first truly serious accessories ever in the U.S. for the AK platform. Magpul for this example has chosen to consider the untold thousands, and growing number, of UltiMAK AK optic mount users by designing their AK handguards with the UltiMAK system in mind. Kudos to Magpul for discerning the market and responding to it.

Q: How come your M6 mounts won't fit Universal and other commercially made Carbines from the 1960s and ‘70s?

A: The vast majority of the commercially made M1 Carbine barrels from the 1960s through the 1980s have different dimensions than the GI barrels that our M6-B and M6-BM were designed for. This includes all carbines made by Universal, Plainfield, Iver Johnson, National Ordnance and Alpine – unless a particular carbine in question was an early production model made with surplus military parts. Please keep in mind, however, that our M6-Sa and M6-SM mounts do fit the commercial M1 Carbines made by Auto Ordnance and Inland Manufacturing’s new production, as they are made to the same specs as the original GI Carbines.

When it comes to Universal, et al. the bulkiness of the barrels, along with major inconsistency of their shapes from one manufacturer to another, creates a serious dilemma for designing an optic mount for them. A potential mount would need to have a fairly high rail height (especially if we wanted to accommodate all possible barrel shapes), and we strive to get the rail heights as low as possible. It’s also worth noting that every single stock on these commercial carbines would need to be modified to fit a mount (in addition to the customization we already do in-house on our Choate stocks).

If you’d like details about when and why commercial manufacturers changed their production during the 1960s, the website M1 Carbines Incorporated offers an explanation:

“More than 426,000 carbines were manufactured by Universal Firearms over a 25 year period from 1961 through 1986. This was 10 years longer and more than three times the quantity manufactured by any other commercial carbine manufacturer. In the beginning the first Universal Firearms carbines were 100% compatible with surplus GI carbine parts, their carbines included many of these parts. As with every other commercial carbine manufacturer, as surplus GI carbine parts became scarce, Universal Firearms began using commercially manufactured substitutes. Unlike other commercial carbine manufacturers, some of the commercially manufactured parts used by Universal Firearms were eventually compatible with the Universal Firearms carbines only and not interchangeable with their surplus GI counterparts.

In 1967 beginning with serial number 100,000 Universal Firearms implemented a major design change to the carbines they produced. The design had been patented by Universal and the majority of parts were no longer compatible with their GI counterparts. The design change was significant enough that the carbine it produced was no longer an “M1 Carbine”. What makes a carbine an M1 Carbine is the use of the design and parts of the original U.S. M1 Carbine, as set forth by U.S. Army Ordnance in the 1940’s and early 1950’s. The Universal Carbine retained the overall outward appearance and ammunition of the U.S. M1 Carbine, but the internal design and parts were a hybrid replica of the M1 Carbine.”

If you are unsure as to whether or not your particular Carbine has a GI pattern barrel, the next entry in this FAQ should clear up the confusion, so please read on.

Q: How do I know if my M1 Carbine has a GI profile barrel and is therefore compatible with your M6 optic mounts?

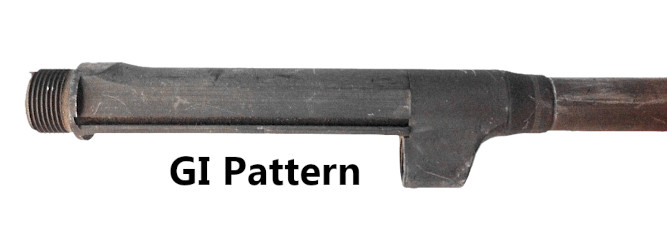

A: The easiest way to tell is by looking at the shape of the barrel. Simply remove the upper handguard and compare the profile of the exposed barrel (that part of the barrel that normally sits inside the handguard) to the two pictures below. If it is a GI pattern barrel, it will look like the one in the upper image, and will be compatible with our mounts. On the other hand, if it is one of the commercial barrels that doesn’t have a GI profile, it will look more like the one in the lower image, being more bulky and heavy, and having a simpler profile. This bulkier area interferes with our mount design and thus such a barrel is not compatible with any of our mounts, nor can the mount itself be altered in any way that will make it fit one of those “chunkier” barrels.

In some cases, you can tell whether our mounts will be compatible based on who the manufacturer was for your Carbine. If your Carbine was made by any of the 1940s government contract manufacturers, then it came originally with a GI barrel, and we designed these mounts for the original Carbines. Here are the makers that we know of that provided Carbines in the 1940s and are all originally “GI spec”. With their original barrel and original wood, they will take our M6-B and M6-BM mounts, with no modifications, nearly 100% of the time. (Very rarely, if the decades-old wood has shrunk more than usual, you might wind up needing one of our shorter mounts – M6-S, M6-Sa, or M6-SM. In this infrequent circumstance, we will gladly swap out the mount for you.)

- General Motors Inland Division (Inland Manufacturing)

- IBM

- Irwin-Pederson Arms

- National Postal Meter

- Quality Hardward & Machine

- Rock-Ola Manufacturing

- Saginaw Steering Gear, General Motors (Saginaw, MI)

- Saginaw Steering Gear, General Motors (Grand Rapids, MI)

- Standard Products

- Underwood-Elliot Fischer Co.

- Winchester Repeating Arms (WRA)

Then there are the more recently produced commercially made M1 Carbines that were also made to GI specs. If your Carbine was made by any one of the following, then it too originally came with a GI profile barrel and will fit with our M6-S, M6-Sa, and M6-SM. (Note that most or all Carbines from these manufacturers will require some wood removal from the inside of the stock forend to make room for the UltiMAK barrel clamps. However, we sell synthetic Choate folding stocks that we’ve pre-machined to accept the M6 mounts on any Carbine without modification.)

- IAI (Israeli Arms International)

- IMI (Israeli Military Industries)

- Auto Ordnance

- Inland Manufacturing Company (not the old one, but the currently operating one, selling new Carbines today)

Finally, the older commercially-made Carbines listed below, made from the early 1960s through the ‘80s, can have either a GI (UltiMAK compatible) barrel profile, or a non-compatible commercial profile (it’s a long story; see our other FAQ entry about commercial carbines if interested). Most of these, however, are NOT compatible. If you own one of the following Carbines, the barrel will probably resemble the one on the lower image (and not be compatible) unless it was fitted with a GI surplus barrel, which some very small portion of them were in the earlier production years. (Most, if not all, of the few that will fit our mounts, will require wood alteration of the stock in a manner similar to that mentioned in the previous paragraph.)

- Universal

- Plainfield

- Iver Johnson

- Alpine

- National Ordnance

Q: Why doesn’t the rail extend all the way back to the receiver on some mounts?

A: Taking the Picatinny rail to the full length of the mount would be physically impossible without raising the height of the rail considerably. In other words, it would require an entirely different mount. Since one of our main objectives is to have the rail as low as possible, we considered the loss of a few slots’ worth of rail length to be insignificant compared to the benefits of having the optical sight axis low enough that a cheek riser would never be needed or even desired. And of course, the low profile rail is why many of our mounts make co-witnessing with factory iron sights possible. With our current design, if we were to simply add extra rail length all the way to the back end of the mount, we’d be cutting all the way through the mount (in fact, the Picatinny undercut would even have to remove material from the rifle barrel itself).

You’ll see this design choice in each of our “Garand family” mounts aside from the M6 series. This includes the M4 & M5 (Ruger Minis), the M8 (M-14/M1A) and the M12 (M1 Garand). In each case, the mount is so low into the barrel profile that there are places we either cannot have a rail, or must forgo a cross-slot or two. This is how we achieve the “maximum lowness” of our mounts. To put it in the proverbial words of a famous software company, “It’s a feature, not a bug”. If you want a mount that’s jacked up enough to have a full-length rail, there are companies out there that offer them, but keep in mind you’ll be ruining your cheekweld unless you also invest in a cheek riser for the buttstock (and co-witnessing with factory sights would not be an option).

Q: Why don't you publish torque specs in your installation instructions or on your website?

A: Our products were designed to be installed by the average user, and the average user does not have an inch-pound torque wrench, nor does he need one if he follows the supplied instructions thoughtfully. If you want numbers, however, the SAE (Society of American Engineers) publishes standard torque specs for all SAE threads. In this case you’re using alloy steel screws in alloy steel clamps. Choose a setting that is near, but not quite all the way up to, the high end of the published range for that scenario. The threads for each of our mounts are as follows:

- All AK piston tube optic mount screws: #8–32

- M4-B, M4-S and M5-B optic mount gas block screws: #8–36

- M4-B, M4-S and M5-B clamp screws (rear screws): #6–32

- All M6 optic mounts for .30 Carbine: #8–32

- M8 optic mount for M14/M1A, Front and middle clamp screws: #10–32

- M8 Rear clamps screws: #6–32

- M12 optic mount for M1 Garand, both clamps: #10–32

Otherwise, simply get the screws “good and tight”, or about as tight as you can reasonably get them while using the supplied Allen wrench, and you’ll be golden. You’ll know that you’ve gone too far if you break a screw. We supply an extra one in case of that unlikely event.

As a related aside, thread locking compound is *not* required on any of our AK piston tube optic mounts, as they are self-locking due to the geometry of the system. Go ahead and use thread locker for our other mounts if you wish, but all of our testing was done without it and we’ve never had a problem. Basically, if you have a screw come loose, it’s because you failed to tighten it adequately. The one exception would be the set screw (or grub screw) at the rear of the ACR2 modular rail – go ahead and use thread locker there, because you’re not “tightening” it in the strict sense of the word.

Q: Do you make a mount for my Saiga AK?

A: The UltiMAK M1-B is the correct optic mount for a Saiga based on the AKM pattern, of any cosmetic configuration, chambered in 5.45, 5.56 or 7.62 x 39mm (but not for the 308 Win, which has a unique barrel profile). However, if you have the factory Sporter handguard (no upper handguard, with a long lower, and no forend cap) that handguard will interfere with the optic mount. You have several options in dealing with this:

1. Use an UltiMAK ACR2 modular AK lower, which is compatible with the optic mount by design. It comes with its own attachment system, so you don’t need any other hardware to make it work on your Saiga. Any of the three ACR2 lengths, as ordered for stamped receivers, will work on your Saiga. The ACR2 lowers can all be found on the AK Mounts page.

2. Use the Zhukov lower handguard from Magpul. It too is UltiMAK compatible, and comes with its own attachment system.

3. Obtain a “bolt-on AK lower handguard retainer.” (You might use that as your internet search phrase to quickly track one down). We prefer the clamshell designs, but any of them will work. It will allow you to use a standard AK lower handguard on a Saiga without having to remove the gas block, sight block, and so on. Not all lower handguards are UltiMAK compatible, but the handguards we sell are.

4. Cut down the original handguard from the top, by about a half inch over a length of about four inches. This will be immediately obvious once you have the optic mount in hand.

So as you see, you have several good options there. If you have one of the Arsenal SGL model Saigas though, it is currently in standard AK configuration and you’re already good to go.

Q: Which mount fits my Palmetto State Armory AKM?

A: The UltiMAK M1-B is the correct optic mount for your PSA AK (GF3, 4, 5). However, we have noticed a recurring issue with the PSAKs:

Although they have the correct barrel diameter (and thus do not need our standard SH-1 shim set), they may have either the gas chamber higher over the bore compared to other ComBloc AKs, or a carrier that is slightly different. Regardless, this unique variance sometimes causes the piston to bind as the UltiMAK clamp screws are tightened; no matter how carefully the mount is positioned side-to-side for alignment with the gas chamber.

There are two reliable solutions, both of which involve making a shim that fits between the “pedestals” (or “feet”) of the mount and the top of the barrel. We’ve had several PSAK owners use these methods to solve the problem. (Please don’t try using our SH-1 shim set for this purpose; it is much too thick).

Method #1: use scissors to cut several long rectangle strips out of an aluminum beverage can. They must be sized to fit underneath the entire surface of both of the “pedestals” under the mount. Three or four layers will be required to raise the mount up off of the barrel enough that the piston no longer binds. Side-to-side positioning of the mount is also important, so with the screws only partially tightened, such that you can barely move the mount side-to-side with some force, try to find the “sweet spot” which allows the piston to traverse from the tube into the gas chamber without undue force. Your hand-made shims must be only on top of the barrel, under the mount, and not under the barrel.

Method #2: as an alternative to an aluminum can, is to obtain brass shim stock, which can usually be found at most hardware stores, auto parts stores, hobby supply stores, or machinist’s supply shops. Most commonly it comes in a package of assorted thicknesses. 0.015” to 0.020” (fifteen to twenty thousandths of an inch) should be about right. In that case you should be able to find a single shim of the right thickness, rather than having to stack several layers of aluminum. The brass shim stock is good to have around anyway because it has a plethora of other uses.